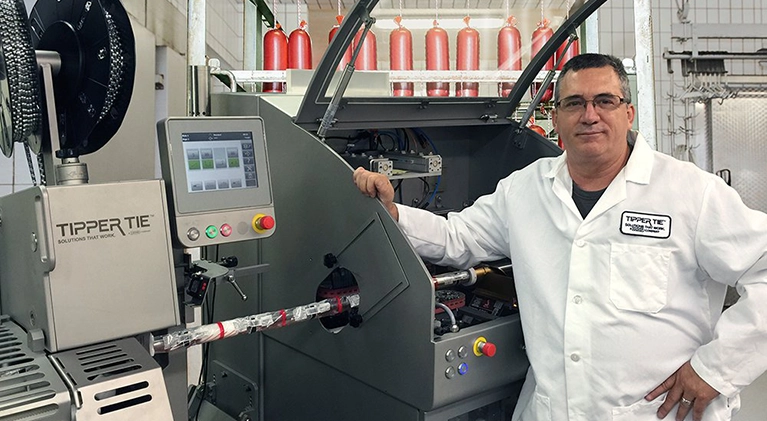

TIPPER TIE is a worldwide supplier of clip packaging machines. Our product range includes a complete line of clippers from tabletop models to fully automated, high speed systems that seal, clip, net, bag and hang a wide variety of products. We have a long history in the food processing industry – especially meat and poultry. Outside of the food industry, TIPPER TIE is a trusted partner to manufacturers of packaged explosives, adhesives, sealants and other industrial products.

Follow Us on:

An Overview of Our Products

Full spectrum of innovative automated and semi-automated clip packaging machines plus closure, hanging, and labeling materials.

Our product range meets all requirements – from table clippers to fully automatic high-speed systems. In addition, we develop numerous products for sealing, netting, packaging and hanging. With many years of experience in the food processing industry.

More than just clipping!

Quality Focus

An unwavering commitment to quality & customer satisfaction is a hallmark of the TIPPER TIE brand.

A Rich History

The History of TIPPER TIE reaches all the way back to the 1950’s.

Subject Matter Expertise

TIPPER TIE provides one-stop, turnkey systems from proposal to installation.